Add to Cart

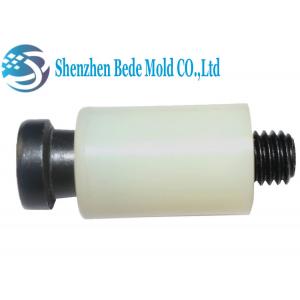

Mould Parting Locks Natural / white Color φ12 Nylon 66 Materials Mould Locks for plastic Injection Molding

Description

The nylon parting lock is part of the friction between the mold and the nylon sleeve by locking the tapered bolt. The mold lock enables the mold to be easily dismantled. During the processing, the friction between the mold and the resin is adjusted by tilting the screw, and the mold can be closed about 50000 times by turning 1/4 circle.

The mold weight and the size of parting locks are as follows:

| mold weight | <100T | 100~500T | 500~1000T | >1000T |

| Size of parting locks | 4pcs*φ12 | 4pcs*φ16 | 4pcs*φ20 | customized |

Size

The parting locks are made up of nylon sleeve and alloy steel bolt. The color of nylon sleeve is white, yellow, red and blue.

The color and performance of parting locks are as follows:

| white | Neutral | red | Temperature resistance |

| yellow | Wear-resisting | blue | High temperature resistance |

| Size D | H/mm | L/mm | N/mm | M/mm |

| φ12 | 19 | 36 | 11 | 6 |

Materials

The bolts are made of alloy steel and have excellent tensile strength. They have a hexagonal cup head for easy installation and removal. The thread adopts international standards and has strong applicability. Customized services are available.

The nylon sleeves are produced by PA66 and special additives, different colors have the different characteristics.

| materials of bolt | alloy steel | Color | natural |

| materials of sleeve | Nylon-66 | Size | φ16 |

Mounting method

1. Insert the resin sleeve into the movable side of the template approximately 3 mm.

2. Create a hole in the fixed side of the template and complete it to reduce the internal surface roughness.

3. To maintain the durability of the mold parting lock, perform R chamfering on the entrance edge instead of C chamfering.

4. PLBS bushings specifically designed for use with this split lock help to replace the R chamfer and surface finish process. The taper bolt of this mold opening controller can be tightened or loosened to adjust the tension.

Attention

1. The sleeve of parting locks are used special nylon material, has good wear resistance and heat resistance, although the nylon sleeve heat resistance temperature is 150, but in the actual use process, because of the continuous effect of the locking stress of conical bolts, durability of the nylon sleeve will be reduced, so it general used below 80℃.

2. Do NOT add lubricating oil on nylon sleeve.

Packing and Shipping

The parting locks are packaged with plastic boxes or PE bags as the pictrue show, and customized package is welcome.

About the shipping, all the well-known express companies and ocean shipping can be selected, but in remote areas, we can only use EMS.